Nas granxas de galiñas, a xestión da ventilación dos galiñeiros é crucial.Ventilación de túnelesé un método de ventilación eficaz, especialmente axeitado para granxas de galiñas poñedoras a grande escala. Analicemos a necesidade da ventilación en túneles nas granxas de polos.

1. A función da ventilación:

Proporcionar osíxeno fresco:O metabolismo das galiñas require respirar osíxeno e expulsar dióxido de carbono. A ventilación proporciona unha fonte de osíxeno ás galiñas.

Descarga de gases residuais sucios:A ventilación elimina o amoníaco, o dióxido de carbono, o sulfuro de hidróxeno e outros gases residuais do galiñeiro.

Control do po:Unha boa ventilación pode axudar a reducir a acumulación de po no galiñeiro.

Reducir a humidade interior:Unha ventilación axeitada pode regular a humidade e manter un ambiente confortable.

Regula a temperatura dentro da casa e fai que a temperatura sexa uniforme en todas as partes da casa: a ventilación axuda a expulsar os gases de escape da casa no momento adecuado e, ao mesmo tempo, fai que a temperatura sexa uniforme en todas as partes da casa.

2. Método de ventilación:

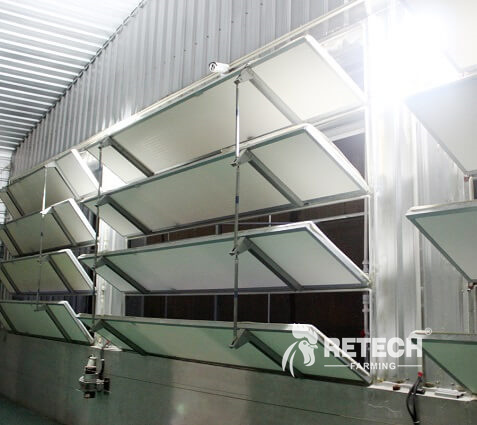

Ventilación do túnel:A ventilación en túnel é un método de ventilación lonxitudinal que instala unha cortina de auga nun extremo do galiñeiro e dispón un ventilador no outro extremo para unha extracción de presión negativa. Este sistema é axeitado para a máxima ventilación do galiñeiro no verán.

Ventilación mixta:Ademais da ventilación lonxitudinal, un certo número deentradas de aireinstálanse nas paredes laterais do galiñeiro e instálanse 1 ou 2 extractores no medio para unha ventilación mínima no inverno. Segundo as necesidades da tempada, pódese converter a ventilación horizontal e vertical, e o tamaño do interruptor da porta de aire e o modo de ventilación poden incluso ser controlados automaticamente polo ordenador.

3. Xestión da ventilación cruzada "mínima" no inverno:

O foco dos galiñeiros no inverno é o illamento, pero non se pode ignorar a ventilación. Para equilibrar o illamento e a ventilación, requírese un patrón de ventilación cruzada con ventilación "minimizada".

O principio de empregar o volume mínimo de ventilación é instalar un controlador de tempo de ventilación de "minimización" baseado no control do controlador de temperatura. Isto garante unha calidade do aire e unha temperatura uniformes no galiñeiro.

En resumo, a ventilación en túnel é realmente necesaria nas granxas de galiñas. Pode mellorar a calidade do aire, a temperatura e a humidade no galiñeiro e mellorar o rendemento produtivo das galiñas.

In granxas de galiñas, a localización das aberturas de ventilación e as entradas de aire é crucial. Aquí tes algunhas suxestións para configurar as túas aberturas de ventilación e as entradas de aire.

4. Localización da entrada de aire:

Boa calidade do aire exterior:A entrada de aire debe estar situada nun lugar con boa calidade do aire exterior.

Lado de saída de aire a barlovento:A entrada de aire debe estar máis baixa que a saída de aire e situada no lado que dá ao vento respecto á saída de aire. Se as elevacións da entrada e as saídas de escape de aire son similares, débense seleccionar direccións diferentes.

Evitar estar enfrontado a zonas de sombra aerodinámica e zonas de presión positiva:A saída de aire non debe estar orientada cara a zonas de sombra aerodinámicas exteriores nin cara a zonas de presión positiva.

Axuste da marxe da persiana:As marxes das reixas das saídas de aire de entrada e saída deben axustarse de acordo coas normas pertinentes.

5. Altura da entrada de aire:

A distancia entre a parte inferior da entrada de aire e o chan exterior non debe ser inferior a 2 metros. Se a entrada de aire está situada nunha zona verde, a parte inferior non debe estar a menos de 1 metro do chan.

6. Localización da saída de aire:

A saída de escape debe estar lonxe das persoas maiores, das zonas de actividades infantís, das fiestras exteriores adxacentes que se poidan abrir e das entradas e saídas de persoal clave.

Se a saída de escape está preto da zona de actividades ao aire libre, a parte inferior da saída de escape da garaxe subterránea non debe estar a menos de 2,5 metros do chan exterior e a parte inferior doutras saídas que eliminan a calor e a humidade residuais non debe estar a menos de 2,0 metros do chan.

7. Determinación da velocidade do vento:

A determinación da velocidade do vento na saída de aire debe considerarse exhaustivamente en función das propiedades funcionais do edificio, os estándares de avaliación do ruído e o volume máximo de aire en funcionamento normal.

En resumo, as aberturas e as entradas de aire deben colocarse en lugares axeitados segundo as circunstancias específicas para garantir que a calidade do aire, a temperatura e a humidade no galiñeiro se controlen eficazmente e para mellorar o rendemento produtivo das galiñas.

Un éxitoproxecto chave en manOs galiñeiros inclúen unha construción moderna, sistemas fiables de alimentación e auga, iluminación de aforro de enerxía, ventilación eficaz e ferramentas de xestión agrícola.

Data de publicación: 29 de marzo de 2024